First rubber powered airplane was converted from glider.

Foam rubber powered plane with propeller made from cottage cheese container.

Foam rubber powered plane with propeller made from cottage cheese container.

New 8-3-2015 New Foam with Balsa Fuselage Airplane With Great Promise

Check Out Article Here: Fantastic Foam Flyer

Video of Phases of Flight – 75 second Flight

Note: For details on constructing the airplane refer to the article on this website Foam and Straw Gliders. I would suggest using a balsa strip 1/8″ thick by 3/8″ wide for the fuselage. Using a bamboo skewer inside of the plastic straw will work for the fuselage but it will be more difficult to attach the propeller assembly.

Refer to that article also for suggestions on how to adjust the airplane.

Combine a lesson of the basics of flight and practical math in

Basic Aerodynamics With a Lesson

I am mentioned in this new book available from Amazon:

Components for This Project

Propellers for Rubber Powered Airplane

|

|

|

| Guillow ,Midwest, and Sig propellers with nose piece included. | The last batch of propellers purchased from Sig Manufacturing, I called for volume price on 200. |

Most people will purchase a commercially manufactured propeller distributed from Sig Manufacturing or Midwest products. Guillow’s also sells propeller assemblies but these tend to be heavier but they certainly will work well. If you have a damaged Guillow’s all balsa airplane that is damaged beyond reasonable repair that could be a source for a propeller, some of these come with landing gear assembly with wheels. Silver colored Peck propellers are sold from a number of sources but these propellers do not include the nose piece. Some people carve their own propellers from balsa or make a propeller from a plastic bottle.

Rubber Motor

|

|

|

| Rubber strip comes from FAI Model Supply. It can be purchased by weight or in smaller packages. 1/8″ or 3/32″ is the suggested width. | For hand winding it is easiest to make the loop to fit from rear of prop shaft to the rear hook with little slack rubber hanging down. |

Rubber Width

Rubber strip is sold in a number of various widths but the most useful for use in the foam planes will be either 3/32” width or 1/8” width preference would be 1/8” for hand winding. Rubber strip can be purchased in packages of a certain length or by weight in a box of ½ or 1 pound weight.

The loop of rubber strip that powers a model airplane appears to be a pretty simple power source but without understanding the basics it will not work very well. First if you can select a width of rubber either 3/32” width or 1/8” rubber strip will most likely be used to turn a plastic propeller that is either 5 ½” or 6” diameter. The next decision is how long the loop of rubber will be. It is possible to use a loop that is much longer than the distance from the rear of the propeller shaft to the rear hook which results in the rubber hanging down with lots of slack. With a longer rubber motor which can be 1 ½ times the length from propeller shaft to rear hook this will give a longer duration of motor run. In actual practice with kids this never seems to work very well unless they are using a mechanical winder and doing “stretch winding”.

To wind a longer motor by hand you need to be holding the slack rubber with part of one hand while winding the propeller with the index finger in the other hand until the slack is drawn up. From experience for planes that will be wound by hand it is best to make the loop the same length as the distance between shaft and rear hook. Lubricating the rubber motor will prolong the life of the rubber motor but for most of the workshops I skip this step. To wind the rubber motor spin the propeller clockwise, it is best to count the turns or at least observe the layer of knots that have been created in the rubber. Maybe it is because we live in a digital world but I find the need to clarify that clockwise is to the right. The model airplane does not fly well when it is launched with the propeller trying to push it backwards because rubber was wound the wrong direction.

Another issue which may seem like common sense but kids have a problem with is having the knot in the rubber motor attached to the propeller shaft. It must be on the rear hook, or the propeller shaft will not turn smoothly. Even with the rubber placed correctly it can sometimes move up the loop in the rear of the propeller shaft causing the motor to bind and not spin easily.

Lubricating Rubber Motors

For longer life and better performance of the rubber motor it helps to lubricate the rubber motor. I use a spray used for cleaning and protecting car interiors such as Armorall or Son of a Gun.

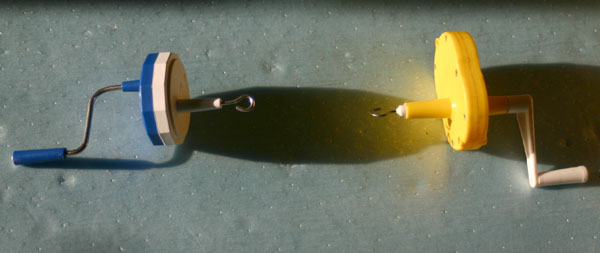

Using a Winder

Although it is possible to wind the rubber motor by turning the propeller with your index finger clockwise, it is much more efficient to use a device known as a “winder”. The winder has a crank that turns gears, this turns the rubber motor faster than you turn the hand crank. Rubber is stretched so that it becomes thinner and more turns can be cranked into the rubber.

To get maximum turns in rubber, the rubber is stretched to a length of 3 to 4 times the un-stretched length. To extend the life of the rubber and for smoother unwinding, the rubber should be lubricated before winding. Many things have been tried but silicone based rubber protectant such as Armorall or Son of a Gun are easy to find and use. The rubber motor is placed in a plastic bag and then the rubber protectant is sprayed in the bag, the rubber is worked inside the bag.

Calculating How Many Turns Can be Wound in the Rubber Motor

For example: maximum turns per inch for 3/32″ rubber is 129, for our rubber motor 10″ long, maximum turns would be 1290. For sport flying 80% would result in 1032 turns.

Rear Hook for Rubber Motor

In every rubber powered model airplane there needs to be a method to attach the rubber motor at the opposite end of the rubber motor from the propeller. It is preferable that it is easy for the rubber to be easily attached or detached at this spot but that the rubber does not fall off as the tension slackens. This part of the model airplane is commonly known as the “rear hook”. In kit airplanes this will often come pre-bent from music wire but I normally make rear hooks by bending up paperclip wire. Straight pins can also be bent up although some airplanes show just using the straight pin inserted into the balsa motor stick at an angle.

Using Glue Instead of Tape

In my first article on Foam and Straw Gliders I showed using masking tape to assemble the glider. This will also work for the rubber powered foam airplanes but it might be better to use some type of adhesive to keep the parts together especially if it is a larger airplane. For the classes I have taught we have used the low temperature hot melt glue guns. This is hardens fast – maybe a couple of minutes before glue joint is solid but there is the danger of coming in contact with the hot tip of the glue gun or the glue.

There are foam safe versions of CA or what is commonly known as “super glue” but this is expensive and can be dangerous. Model cement types of glue of sold in hobby shops or hardware stores will actually attack the foam. If glue drying time is not an issue a white glue or the white tacky type of glue sold in craft stores will work.

News Flash 4-22-2015

Check out my new webpage on the Guillow’s Model Airplanes

Images of Rubber Powered Foam Plane Activities

|

|

|

|

| College for Kids Class Built Plane Pictured on the Right | Balsa Motor Stick used With Foam Plates Flying Surfaces |

|

|

| Rubber powered airplanes climbing high at summer camp. | Campers built two planes; FPG-9 and rubber powered foam plane. |

|

|

| Foam Planes on Display at STEM Day at MN State Fair | In Front of my booth at STEM Day at MN State Fair |

What Other People are Doing With Foam Model Airplanes

|

|

| Rubber powered foam airplane by Neil Dennis designer of the Denny Dart series of balsa and tissue covered airplanes. |

Denny Dart II in flight, I have had many students build this airplane. |

|

|

| Gary Hinze Sierra Nevada Special check out article from link below. | Foam Squirrel in flight also by Gary Hinze. |

Recently Created Foam and Balsa Plane by Paul Lachance

New 5-6-2015 Rubber Powered Foam Airplanes in Indonesia

Riyadi Lembang Pictures from His Blog : Lembang Aeromodelling

Ken Achee had grandsons building and flying some foam airplanes.

Links to Additional Information on Foam Model Airplanes

Gary Hinze article on foam Sierra Nevada Special Foam Plane

Gary Hinze VERY Detailed article on Foam Squirrels (Model Plane)

Gary Hinze article Simple Hand Launched Foam Plate Gliders

Darcy Whyte Foam Squirrel Article

Blog Article About Neil Dennis and the Denny Dart

Blog Article on College for Kids Class Using Foam Planes

Want to learn More and Connect With Others on Simple Foam Free Flight Airplanes

Click Here to Join Facebook Group for these types of model airplanes.

College for Kids 2014 Pictures

Foam Rubber Powered Planes Sold in Stores

Craft stores and hobby shops often sell foam rubber powered airplanes and foam gliders that are easy to assemble. The main problem I have seen in these airplanes are they are too heavy, the rubber motor provided might not be suitable also.

This planes sold by Estes has full width fuselage but could use more wing area and larger propeller.

This plane from Lyonaeec can be flown as a monoplane or as biplane the motor stick and plastic parts are rather heavy.

Video of First Plane I Built, Rather Amazing How Well it Flies

Hi! Would you mind if I share your blog with my zynga group?

There’s a lot of folks that I think would really appreciate

your content. Please let me know. Thank you

Hi there to every body, it’s my first pay a quick visit of

this webpage; this webpage includes awesome and actually

good information for readers.

I always used to read post in news papers but now as

I am a user of net therefore from now I am using net for articles or reviews, thanks to web.

Right here is the right web site for anyone who wants to

understand this topic. You understand a whole lot its

almost tough to argue with you (not that I personally would want to…HaHa).

You certainly put a new spin on a subject which has been discussed for years.

Excellent stuff, just great!

Thanks for the thorough guide. My brother’s physics class had a contest of the longest flying plane and there was one contestant with foam flying surfaces. His plane was a bit slower but flew more stable and floated longer than the others.

Thank you Aubrey for your comment I really need to add to this article with more details and a sample plan. Foam models can really fly well if designed properly.

Bill Kuhl

I do need to add to this and I will, more images are needed too.

Bill

You need to take part in a contest for one of the most useful blogs on the net.

I am going to highly recommend this site!

Hello There. I found your blog using msn. This is an extremely well written article.

I’ll make sure to bookmark it and return to read more of your useful info.

Thanks for the post. I’ll definitely comeback.

Fantastic webpage on a how to guidebook how t making foam airplanes. I look forward to sharing our progress.

Thank you, I do plan to expand on this webpage. And by all means do share this.

Bill Kuhl

great hobby. i want to teach my son how to make rubber band flying aeroplanes and develop to solid models until he grows to be an aircraft engineer.

Hi,

Excellent advice and inspiration for helping kids to get into planes. I started as a kid in the early ’70’s buying stick rubber powered balsa planes. I forget the make but they were very light with very efficient propellors, looking like the SIG you show here. The wings and tail were 1/32″ thick and clipped into a simple plastic fitting which slid back and forth on the 1/4″ x 1/8″ medium balsa fuselage for balancing. The duration was pretty good and I used to experiment with making different sized wings and rubber motors. I used castor oil for rubber lubricant. I remember warping the wings and tail using my hot breath to create aerofoil lifting shape for the wings and making the tail turn or lift / dive. Great memories which in the fullness of time took me into a career in science and engineering. Keep up the good work. Steve

I also make a rubber band plane

Check my tutorial for bamboo indoor living room airplane! Easy to build.

from where did you got the propeller??????????

The best deal for multiple propellers is probably from PITSCO

PITSCO

Wonderful web site. A lot of helpful info here.

I am sending it to a few buddies ans additionally sharing in delicious.

And obviously, thank you in your effort!

Some truly interesting information, well written and loosely user pleasant.